A Lifelong Passion

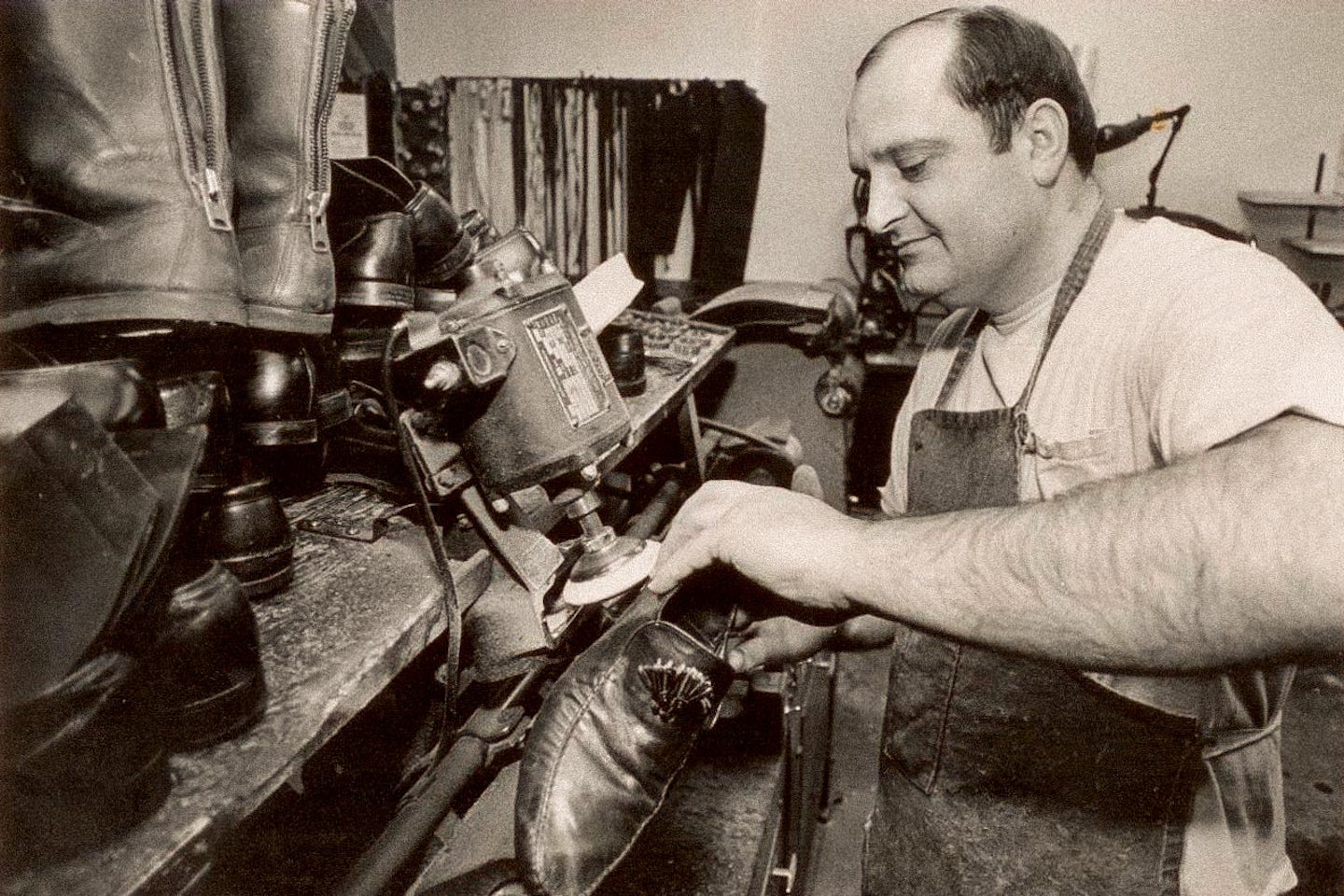

The son of a cobbler, Oak Street Bootmakers Founder and Design Director George Vlagos apprenticed at his father’s shop. From his father, George learned how shoes are made—and how they used to be made. Today, George works to preserve the heritage of fine American shoemaking through thoughtfully designed and attentively crafted shoes and boots.